Contact Us

FIREPROOF ACP

- Product Type: FIREPROOF ACP

- Place of origin:

- Model No:

- Price Terms:

- Payment Terms:

- Package:

- Minimum Order:

- Delivery Time:

- Brand Name:

- Inquire Online

Products Information

FIREPROOF ACP

FOR MORE FIRE SAFETY

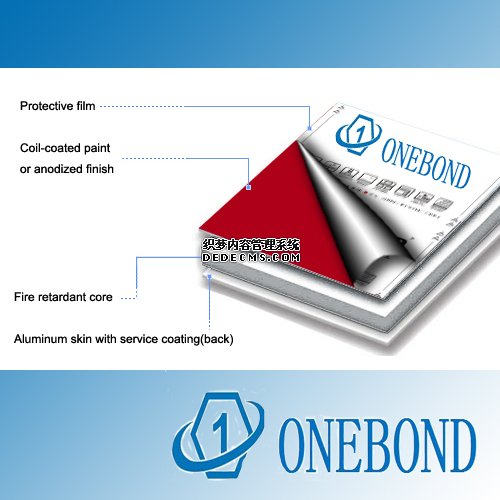

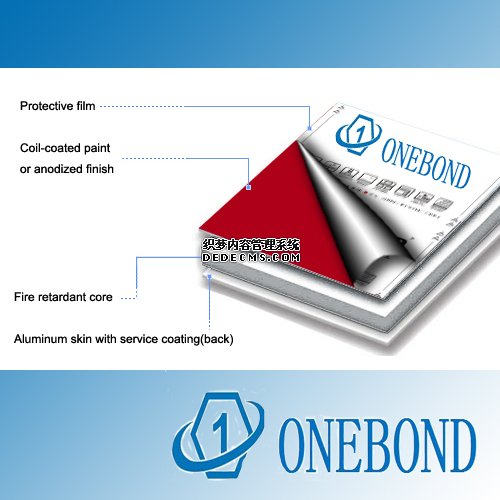

Fireproof Aluminium Composite Panel is a fire-safe material with a flame-retardant mineral core or non-combustible core to prevent the proliferation of flames and restrict the development of smoke detrimental to evacuation activities. This is developed exclusively for the higher requirements of the fire regulation in architecture. It meets the BS, ASTM standard testing by SGS Lab, and reach GB 8624-2006 B-s1, d0, t0 grade and Non-combustible Class A. Inherit the advantage of Aluminum composite panels characteristics, Fireproof Aluminium Composite Panel is an ideal fire-safe material for interior/exterior architecture.

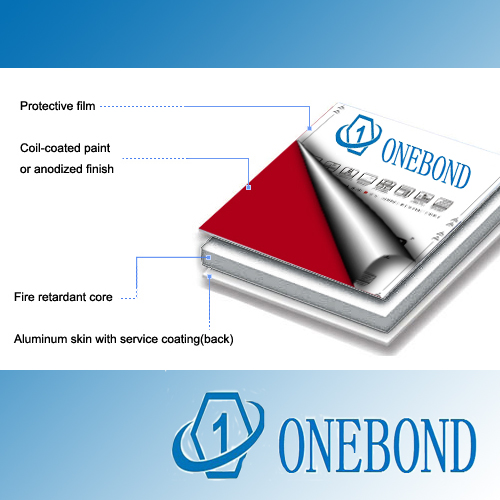

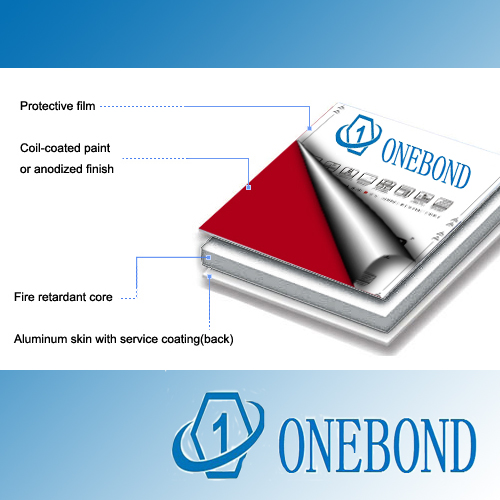

Constitution structure:

Standard Products:

For Exterior: 1220X2440X4MM, al: 0.3mm,0.4mm,0.50MM, PVDF

For Interior: 1220X2440X3MM, al: 0.10mm,0.12MM,0.18MM.0.21MM PE

Products Available:

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm

Length: can be customized

Width: 800mm~1570mm

Aluminum thickness: 0.12mm, 0.18MM ,0.21mm, 0.30mm, 0.40mm, 0.50mm

Coating: Polyester coating, Fluorocarbon coating.

Scope of Application: Internal and external decoration for all kinds of buildings, airports, ceilings, tunnels, billboards, doors, furniture, car bodies, ships, etc.

Cutting: Cut with a saw, cutter, or trimmer.

Cleaning and Maintenance: Clean with water or neutral cleaner, using a soft cloth. Do not use force. Do not use a knife or other sharp object.

FR Aluminum composite panel .

Completely meets the fire safefy requirement according to BS 476 Part 6, ASTM E-84, and China GB8624 standards

FR Conforms to:

Tested according to BS, ASTM Standard:

BS : British Standard; ASTM : American Society for Testing and Materials

Tested according to China Natioanl fire-safty standard

Conclusion:

Since the sample receives a Flame Spread of 10 and a smoke Developed Value of 15, it will fall into the Class A Interior Wall & Ceiling Finish Category. And completely meets the China GB/T 8624, Grade B-s1, d0, t0 standards require.

For more details, please refer to a full set of data sheets or consult our nearest technical advisor for advice.

FOR MORE FIRE SAFETY

Fireproof Aluminium Composite Panel is a fire-safe material with a flame-retardant mineral core or non-combustible core to prevent the proliferation of flames and restrict the development of smoke detrimental to evacuation activities. This is developed exclusively for the higher requirements of the fire regulation in architecture. It meets the BS, ASTM standard testing by SGS Lab, and reach GB 8624-2006 B-s1, d0, t0 grade and Non-combustible Class A. Inherit the advantage of Aluminum composite panels characteristics, Fireproof Aluminium Composite Panel is an ideal fire-safe material for interior/exterior architecture.

Constitution structure:

Standard Products:

For Exterior: 1220X2440X4MM, al: 0.3mm,0.4mm,0.50MM, PVDF

For Interior: 1220X2440X3MM, al: 0.10mm,0.12MM,0.18MM.0.21MM PE

Products Available:

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm

Length: can be customized

Width: 800mm~1570mm

Aluminum thickness: 0.12mm, 0.18MM ,0.21mm, 0.30mm, 0.40mm, 0.50mm

Coating: Polyester coating, Fluorocarbon coating.

Scope of Application: Internal and external decoration for all kinds of buildings, airports, ceilings, tunnels, billboards, doors, furniture, car bodies, ships, etc.

Cutting: Cut with a saw, cutter, or trimmer.

Cleaning and Maintenance: Clean with water or neutral cleaner, using a soft cloth. Do not use force. Do not use a knife or other sharp object.

FR Aluminum composite panel .

Completely meets the fire safefy requirement according to BS 476 Part 6, ASTM E-84, and China GB8624 standards

FR Conforms to:

| Country | Standard | Grade |

| China | GB8624 | B-s1,d0,t0 |

| Europe | EN13501 | B-s1,d0 |

| U.S.A | ASTM E84 | A |

| U.k | BS 476 | 0,1 |

Tested according to BS, ASTM Standard:

| TESTING ITEMS | TEST CONDITION | RESULT | CONCLUSION | STANDARD |

| Fire safety test | BS 476 Part 6: 1989 | Total fire propagation index: 0.05 | Class 0 | BS 476:Part 6:1989 |

| Fire safety test | Relative Humidity of 50 10F Temperature of 23 2 C | Flame spread at 1.5min: 60mm | Class 1 | BS 476:Part 7:1997 |

| Final flame spread: 60mm | ||||

| Fire safety test | Relative Humidity of 50 5F Temperature of 73 5 C | Flame spread index: 10 | Class A | ASTM E-84-04 |

| Smoke develcped value: 15 |

Tested according to China Natioanl fire-safty standard

| NO | Test Item | Test Methods | B Grade Index | Test Value | Tesult | |

| 1 | FIGRA(FIGRA),W/S | GB/T20284-2006 | B | ≤120 | 3 | Passed |

| 2 | THR600S(THR600S),m | GB/T20284-2006 | ≤7.5 | 0.4 | ||

| 3 | LFS,m | GB/T20284-2006 | <sample size | Conform | ||

| 4 | Fs,mm | GB/T20284-88 | ≤150 | 0 | ||

| 5 | SMOGRA, ㎡/s2 | GB/T20284-2006 | S1 | ≤30 | 0 | Passed |

| 6 | TSP600s, ㎡ | GB/T20284-2006 | ≤50 | 35 | ||

| 7 | Burning Drop | GB/T20284-2006 | D0 | 600s?No drop | Conform | Passed |

| 8 | Filter Paper Burn or Not | GB/T20286-88 | Filter Paper NO Burn | Conform | ||

| 9 | Smoke Toxicity,Grade | GB/T20285-2006 | To | Conform to ZA1 | ZA1 | / |

| 10 | Core heating Value,MJ/kg | GB/T14402-93 | / | 11.7 | ||

| AL heating Value,M/kg | GB/T14402-93 | 0 | ||||

| Coating Heating Value,MJ/㎡ | GB/T14402-93 | 0.4 | ||||

| Panel Heating Value,MJ/kg | GB/T14402-93 | 5.8 | ||||

Conclusion:

Since the sample receives a Flame Spread of 10 and a smoke Developed Value of 15, it will fall into the Class A Interior Wall & Ceiling Finish Category. And completely meets the China GB/T 8624, Grade B-s1, d0, t0 standards require.

For more details, please refer to a full set of data sheets or consult our nearest technical advisor for advice.

Related Products