About ONEBOND

Foam Core Materials Manufacturer

We in-depth understanding XPS PET PU PVC Foam Core Board Composite Sandwich Panel Manufacturer’s mission to provide eco-friendly polystyrene foam products.

Our company is dedicated to reducing waste and promoting sustainability through our foam manufacturing process. We believe in creating high-quality products without harming the environment.

Popular Products

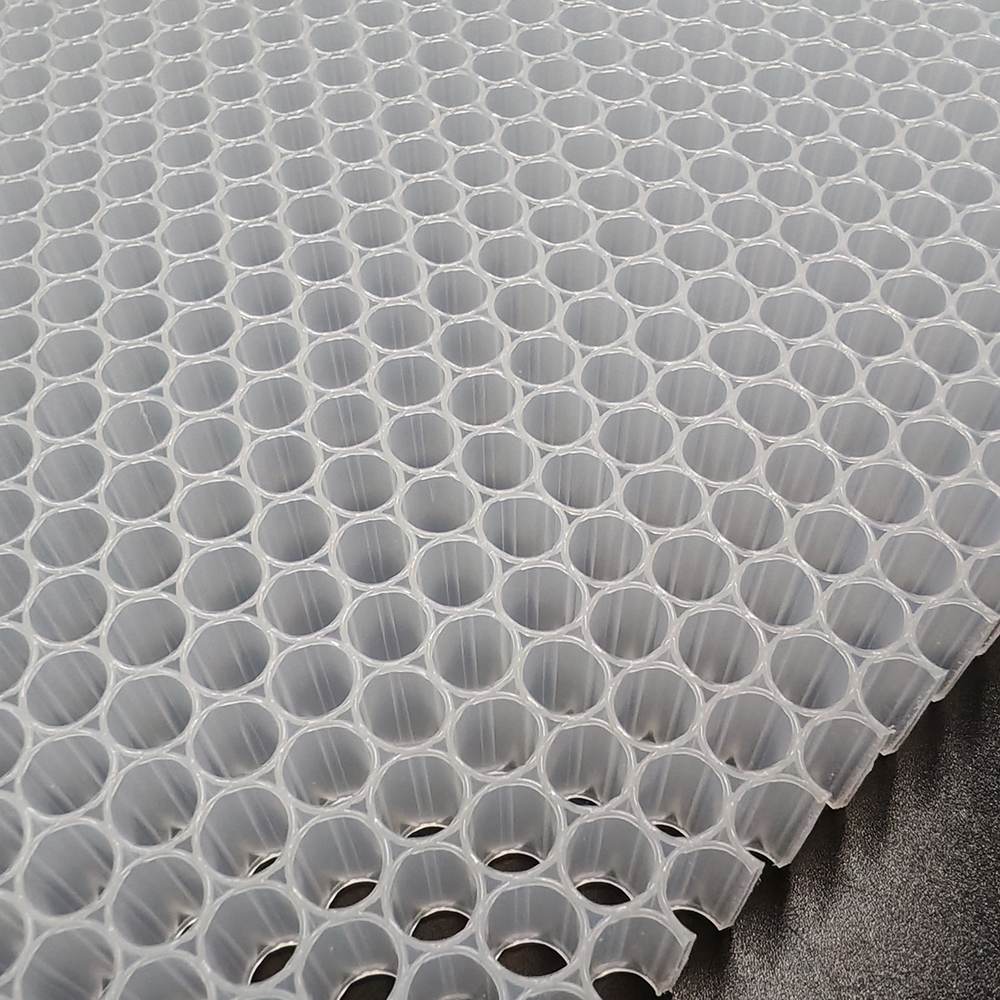

Lightweight, durable, thermally insulating

ONEBOND offers a wide range of composite materials with foam cores and panel skins. We customize the most cost-effective composites based on your project requirements.

Flammability Rating: B1

Enhanced Fire Safety for Critical Applications

Foam Core materials with a Flammability Rating B1 are engineered to meet stringent fire safety requirements while maintaining the lightweight and structural advantages essential to modern composite and sandwich panel systems. Classified as Class B (B1) under commonly referenced fire performance standards, this rating indicates that the material is flame-retardant, exhibiting limited combustibility and significantly reduced flame spread when exposed to fire.

Performing at the Highest Standards:

Optimise the performance and durability of your sandwich panels with Our Core Solutions!

Foam Core is a robust and high-quality material, ideal for insulating industrial buildings. Our experts listen your needs to provide you with tailored solutions. Whether for roof or wall insulation, we adjust mechanical performance according to your requirements.

Standout Features of Foam Core Board

High fire resistance rating

The substance material is evaluated to be level B0, B15, A30, A60 fire resistance, with rating up to 4hrs, it gives off zero hazardous gas, 100% meets and exceeds classification societies regulations and rules.

Sound insulation

Made of light weight composite material, thin as it is, the thickness of 25~100mm panel reduces and absorbs the sound volume of 30dB in the air.

Light weight, high strength

Strong surface hardness, light core weight. Composite rock wool board is made up of galvanized steel sheet, PVC plastic decorative film, adhesive and rock wool compound.

Heat preservation and insulation

Thermal conductivity as low as 0.1. Internal discontinuity between steel sheets and filling compound causes heat chain rupture , the feature helps saving energy in hot area and keeping warm in cold area. Besides it keeps indoor relative humidity stable.

Water proof and moister proof

Under test condition of water flow 0.5L/min• m2, wind pressure 250pa, spray Fountom wet panel for 6 hrs x 2 days, no leakage detected in both sides at all, this material can be used in wet area such as kitchen, toilet and basement.

Simple installation, fast construction

The installation is pure assembling, the panel can be arbitrarily cut according to specification after calculation, greatly reduced construction waste. 20 m2 wallboard can be assembled each day/worker by average, it is saving a lot time and manpower for clients.

Get Product Quotes and Information?

Helping you with the challenges you face, We are trustworthy.

Customized Solutions

New technologies, new materials, new designs

Our professional team can guide you on how to customize your suitable products, analyze the characteristics and applications of various materials, and propose the optimal solution for your specific needs.

ONEBOND your best choice of foam core panels supplier

Superior quality, competitive prices, quick delivery,customer oriented service.

Since

2006

Factory

20000㎡

Workers

100+

equipment

30+

Latest News

From Hulls to Superstructures: How PVC Foam Core Enhances Strength, Longevity, and Safety in Marine Vessels

Introduction Structural performance, safety, and durability are non-negotiable in marine engineering. Marine PVC foam[…]

Lightweighting the Next Generation of Yachts and Workboats: Why PVC Foam Core Is Becoming the Industry Standard

Introduction: The Era of Lightweight Marine Design Fuel economy, emissions reduction, speed, and passenger[…]

Marine-Grade PVC Foam vs. Traditional Core Materials: What Boatbuilders Need to Know in 2026

Introduction: A Changing Materials Landscape in Marine Engineering The marine industry is at a[…]

How Composite Sandwich Structures Are Transforming the Shipbuilding Industry: A Deep Dive into PVC Foam Core Technology

Introduction: A Structural Revolution at Sea The modern shipbuilding industry—across commercial vessels, workboats, leisure[…]

The Ultimate Guide to PVC Foam Core in Modern Boatbuilding: Materials, Applications, and Performance Advantages

Table of Contents 1. Introduction: Why PVC Foam Changed Modern Marine Composites Over the[…]

Why is PVC foam still widely used in boats?

Because it offers the best combination of strength, stiffness, toughness, and processability.